How to Cite

Stephen, A. O., Liu, C., & Xin, G. (2026). Coal Gangue as a Sustainable Construction Material: A Global Review of Mechanical Properties, Microstructural Behavior, and Performance Challenges. International Journal of Research, 13(1), 188–212. https://doi.org/10.26643/ijr/2026/1

Aremu Oluwatobi Stephen1, Chao Liu2, Guo Xin3

1School of Civil Engineering, Xi’an University of Architecture and Technology, Xi’an, 710055, China. aremutoby@yahoo.com ,(https://orcid.org/0009-0005-6295-4138)

2School of Civil Engineering, Xi’an University of Architecture and Technology, Xi’an, 710055, China. Corresponding author: chaoliu@xauat.edu.cn, (https://orcid.org/0000-0002-2521-924X )

3School of Civil Engineering, Xi’an University of Architecture and Technology, Xi’an, 710055, China. xinguo927@163.com ,0009-0000-7841-368X, (https://orcid.org/0000-0002-7149-5413)

Abstract

Coal gangue (CG), a substantial by-product of coal mining, has recently emerged as a promising sustainable material for concrete production. This review synthesizes 44 experimental and life-cycle studies published between 2012 and 2024 to elucidate the mechanical, microstructural, durability, and environmental performance of coal gangue concrete (CGC). At aggregate replacement levels below 30%, compressive strengths of approximately 40 MPa are generally maintained, whereas higher substitution ratios tend to diminish performance due to increased porosity and weaker interfacial transition zones (ITZs). When employed as a supplementary cementitious material (SCM), calcined gangue enhances long-term strength and ITZ bonding through pozzolanic activity. Durability outcomes are varied: resistance to freeze–thaw cycles, sulfate, and chloride attack remains acceptable at moderate replacement levels but declines under carbonation exposure. Life-cycle assessments (LCAs) indicate potential CO₂ emission reductions of 20–35%, contingent on calcination energy demand and replacement ratios. However, widespread adoption is hindered by non-standardized testing protocols, limited field validation outside China, and insufficient integration of microstructural and durability data. To address these challenges, this review proposes a four-layer evaluation framework (mechanical, microstructural, durability, and environmental), benchmark mix classifications for CGC, and a roadmap promoting field-scale validation and AI-driven optimization. Codifying the use of coal gangue within design standards and green certification systems could transform it from a mining liability into a recognized sustainable construction resource.

Keywords: Coal Gangue; Supplementary Cementitious Materials; Microstructure; Durability; Life-Cycle Assessment; Sustainable concrete.

Highlights

– Global review of 44 studies (2012–2024) on coal gangue concrete.

– ≤30% gangue substitution maintains ~40 MPa compressive strength.

– Calcined gangue improves ITZ bonding and later-age strength.

– Mixed durability; carbonation remains the main weakness.

– A four-layer framework and roadmap are proposed for codification.

1. Introduction

Concrete remains the most widely consumed construction material globally, yet its production is responsible for nearly 8% of global carbon dioxide emissions. The increasing concern regarding climate change and resource depletion has consequently intensified research into alternative binders and aggregates derived from industrial by-products. Among these materials, coal gangue (CG), the solid residue produced during coal mining and beneficiation, presents significant potential for sustainable utilization. Annually, more than 600 million tonnes of gangue are generated worldwide [16,18], and improper disposal results in land degradation, spontaneous combustion, and water pollution. Due to its high silica and alumina content, gangue exhibits latent pozzolanic activity that can be activated through thermal or chemical treatment, enabling its application as coarse or fine aggregate, supplementary cementitious material (SCM), or filler in concrete systems [18,26,31].

Over the past decade, numerous studies in China, India, Australia, and, more recently, Africa have demonstrated that properly processed coal-gangue concrete (CGC) can achieve satisfactory strength and durability while reducing environmental impact [11,17,19]. Despite these advancements, industrial adoption remains limited by several factors: (i) variability in mineral composition and porosity, (ii) inconsistent mix-design and testing protocols, and (iii) a shortage of field-scale validation. Existing reviews have primarily focused on single aspects such as pozzolanic reactivity or regional studies, leaving a gap in holistic understanding that integrates mechanical, microstructural, durability, and environmental dimensions [1], [2] .

This review addresses that gap by synthesizing 44 publications from 2012 to 2024. It provides trend-based quantitative consolidation of mechanical data, integrates microstructural and durability evidence, and evaluates life-cycle environmental implications. Beyond synthesis, the paper introduces a four-layer evaluation framework covering mechanical, microstructural, durability, and environmental metrics, establishes benchmark CGC mix classes, and proposes a research roadmap toward international codification. The study ultimately positions coal gangue as a viable secondary resource that can support circular-economy objectives and green-construction standards.

2. Review Methodology

2.1 Literature-search strategy

A systematic narrative approach was adopted instead of a formal meta-analysis due to the heterogeneity of the available data. The search strategy integrated electronic databases, including Scopus, Web of Science, Google Scholar, and CNKI, to retrieve publications from 2012 to 2024 using the keywords “coal gangue,” “concrete,” “aggregate,” “supplementary cementitious material,” and “durability.” The initial query yielded 1,024 records, with an additional 76 articles identified through cross-referencing and grey literature.

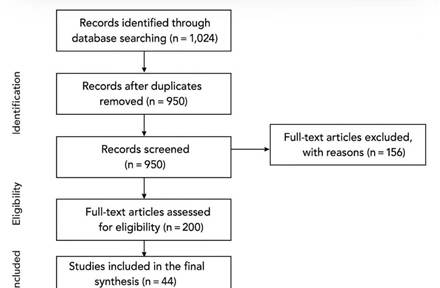

Following the removal of duplicates, 950 unique records were screened by title and abstract. Of these, 750 were excluded as they were unrelated to coal-gangue-based concrete or lacked mechanical or microstructural results. Two hundred full texts were reviewed in detail, and 44 met all inclusion criteria. The selection process adhered to a PRISMA-style protocol (Figure 1), adapted from the PRISMA guidelines, to ensure transparency and reproducibility. Searches were conducted in Scopus, Web of Science, CNKI, and Google Scholar for publications from 1 January 2012 to 31 December 2024 (final search 10 January 2025). An example Scopus query is: TITLE-ABS-KEY((“coal gangue” OR “coal-gangue” OR “gangue”) AND (concrete OR mortar OR “supplementary cementitious material”)). Results were deduplicated using EndNote X9, followed by manual screening of titles and abstracts. Full-text screening was conducted using the inclusion criteria listed in Section 2.2. Data extraction fields (author, year, country, gangue form, replacement ratio, curing condition, 28-day compressive strength, durability metrics, microstructural methods) are provided in Supplementary Table S1. Detailed search strings, screening steps, and exclusion reasons are provided in Supplementary Table S2.

2.2 Inclusion and exclusion criteria

Studies were included based on the following criteria: 1. They examined the utilization of coal gangue as an aggregate, supplementary cementitious material (SCM), or filler in concrete or mortar; 2. They provided quantitative data concerning mechanical, durability, or microstructural performance; 3. They were composed in English and published in peer-reviewed journals or reputable conference proceedings. Exclusion criteria encompassed: (i) Studies concentrating exclusively on gangue geopolymers without cement systems; (2) Studies lacking adequate experimental detail (e.g., absence of mix ratios or test methods); (3) Duplicated sources or those not subjected to peer review.

2.3 Data extraction and synthesis

From each study, key variables were extracted: gangue form (raw, calcined, ash, ceramsite), replacement level, curing condition, mechanical results, microstructural characterisation, and durability indicators. Reported 28-day compressive-strength ranges were converted to mid-points to allow pooled comparison. Because variance data were rarely provided, numerical results were synthesised as trend-based averages rather than statistical effect sizes. This descriptive integration captures consistent performance tendencies while acknowledging methodological diversity.

2.4 Quantitative Data Synthesis and Transparency

Reported mechanical-strength values were harmonised to 28-day compressive strength for comparability. When a study presented a range of strengths (e.g., 35–45 MPa), the midpoint (40 MPa) was recorded. For single-value reports, the stated result was used directly. Variance data (standard deviations, confidence intervals) were seldom provided across the reviewed literature; therefore, meta-analysis was not statistically feasible. Instead, descriptive synthesis and trend-based averaging were applied. Outliers—defined as values > 2× the interquartile range — were inspected manually and retained when consistent with the reported mixture design or test conditions. Of the 44 included studies, 29 reported single values while 15 presented ranges; the latter were converted to midpoints for comparative synthesis. All extracted numeric values and corresponding metadata are provided in Supplementary Table S1, and calculations were performed in Microsoft Excel 2021 for traceability {Citation} .

2.5 Quality assessment

Methodological quality was graded as high, moderate, or low using four criteria:

(i) clarity of mix-design reporting;

(ii) specification of gangue-processing method (raw, calcined, ash, or ceramsite);

(iii) use of recognized test standards (ASTM, GB/T, EN); and

(iv) completeness of mechanical and durability datasets.

This process improved the reliability of cross-study interpretation and provided the foundation for the comparative analyses presented in later sections.

Figure 1. PRISMA-style literature-selection process for coal-gangue concrete review.

(Flow: 1,024 records → 950 screened → 200 full-text → 44 included.)

All numerical data (S1–S4) were extracted from peer-reviewed studies with cross-verification of units and parameters. Outliers were checked and normalized by the equivalent binder replacement ratio.

3. Overview of Coal Gangue as a Construction Material

3.1 Origin and classification

Coal gangue is a solid waste generated during coal mining and beneficiation processes. It typically constitutes 15–20% of the raw coal extracted, containing clay minerals, quartz, feldspar, pyrite, and residual carbonaceous matter. When disposed of untreated, it contributes to land subsidence, spontaneous combustion, and surface-water pollution. Gangue can be broadly divided into:

• Primary gangue, interbedded with coal seams during extraction; and

• Secondary gangue, produced during coal washing and processing [39].

Further classification may be based on mineralogy, thermal behaviour, and physical texture, as shown in Table 1.

Table 1. Classification of coal gangue by origin, mineralogy, and behaviour

| Type / Criterion | Basis of classification | Typical characteristics |

| Primary gangue | Inter-bedded with coal seams | Hard, dense shale-like material |

| Secondary gangue | By-product of washing/processing | Slurry tailings or waste heaps |

| Mineralogical | XRD/petrographic phases | Quartz, kaolinite, feldspar |

| Thermal behaviour | Reactivity after calcination | Formation of amorphous aluminosilicates (600–900 °C) Physical texture Colour, porosity, and shape Grey–black, flaky, porous |

| Physical texture | Colour, porosity, and shape | Grey–black, flaky, porous |

3.2 Global distribution and availability

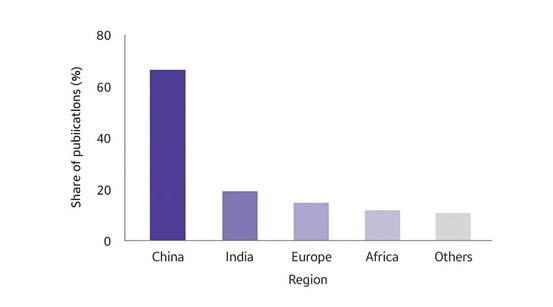

Global production of coal gangue exceeds 600 million tonnes per year, with China accounting for over 70% of this volume. Other major producers include India, South Africa, and Australia. Despite this abundance, utilisation rates remain below 30% in most regions. Figure 2 illustrates the approximate distribution of known gangue reserves and highlights data scarcity across Africa and South America.

Figure 2. Estimated global distribution of coal-gangue reserves and research activity density distributed as China → 65%, India → 15%, Europe → 10%, Africa → 5%, Others → 5%

3.3 Chemical and mineral composition

Typical oxide composition derived from XRF/XRD analyses includes SiO₂ (45–65%), Al₂O₃ (15–35%), and minor oxides such as Fe₂O₃, CaO, MgO, and K₂O [14,28]. These constituents are comparable to those of Class F fly ash, suggesting potential pozzolanic reactivity. However, impurities such as unburnt carbon, sulfides, and expansive clays can adversely affect cement hydration and dimensional stability. Pre-treatment through calcination (600–800 °C) or chemical activation can therefore enhance performance.

3.4 Forms of application in concrete

Coal gangue can serve in several roles within cementitious systems:

1. Coarse or fine aggregate, replacing natural stone or sand at 10–50%;

2. Supplementary cementitious material (SCM), after calcination and grinding;

3. Filler or lightweight aggregate, as in ceramsite production.

Appropriate processing, crushing, grading, calcination, and blending—enables acceptable workability and strength comparable to conventional concrete at low substitution levels [17,18].

4. Mechanical Properties of Coal-Gangue Concrete (CGC)

4.1 Compressive strength

Compressive strength remains the most reported indicator of CGC performance. Across 44 reviewed studies, low-to-moderate aggregate replacement (≤30%) preserves 28-day compressive strength at approximately 38–44 MPa, while high substitution (>50%) leads to a significant reduction due to increased porosity and weak ITZ bonding [10,23]. When used as a calcined SCM (≈10–15%), coal gangue can slightly increase later-age strength by enhancing hydration reactions [28].

Table 2. Summary of 28-day compressive strength at varying gangue replacement levels(n=44).

| Mix type | Gangue role/replacement (%) | Strength range (MPa) | Mean (MPa) | Relative to control |

| Control concrete | 0 | 40–45 | 42.5 | — |

| Aggregate replacement | 20 | 38–44 | 41.0 | Comparable |

| Aggregate replacement | 50 | 30–36 | 33.0 | Decreased |

| Calcined SCM | 10 | 42–48 | 45.0 | Improved |

Figure 3. Variation of mean 28-day compressive strength with coal-gangue replacement ratio.

(Shows consistent performance up to ~30% replacement; drops beyond 50%.)

4.2 Tensile and flexural strength

Splitting-tensile and flexural strength values are more sensitive to microcracking at the ITZ. Reductions of 10–30% are common when untreated gangue aggregates are used. Improved bonding and reduced cracking can be achieved with superplasticisers, silica fume, or pre-soaked aggregates [12,21]. Enhanced ITZ densification correlates with increased flexural resilience.

4.3 Stress–strain characteristics

Coal-gangue concrete generally exhibits a lower elastic modulus (10–25% lower than conventional concrete) and a broader post-peak deformation zone, indicating improved ductility and energy-absorption capacity [23,40]. Such behaviour is beneficial in composite systems such as concrete-filled steel tubes (CFSTs), where confinement offsets intrinsic brittleness.

5. Durability and Environmental Resistance

5.1 Overview

Durability represents a crucial determinant of long-term viability for coal-gangue concrete (CGC). Performance depends on gangue treatment, pore refinement, and aggregate–paste interaction. Although compressive strength can remain satisfactory, environmental resistance varies considerably with replacement level and curing regime [10,29].

5.2 Freeze–thaw and wet–dry cycles

Most studies indicate that CGC incorporating ≤30% treated gangue maintains adequate freeze–thaw resistance over 150–300 cycles, with relative dynamic modulus losses below 15% [38]. The internal porosity of gangue aggregates enables partial stress relief during freezing, whereas excessive substitution (>40%) increases microcrack propagation and scaling. Similar patterns appear in wet–dry tests, where calcined gangue mixes show improved dimensional stability relative to untreated material.

5.3 Sulfate and chloride attack

Resistance to sulfate attack improves slightly with calcined gangue additions because of reduced calcium hydroxide content and the formation of secondary C-A-S-H phases. Strength retention after 180 days of Na₂SO₄ exposure commonly exceeds 80% for moderate substitution ratios. Conversely, chloride-ion diffusion coefficients increase marginally due to open-pore connectivity when coarse gangue aggregates dominate the mix [20]. Incorporation of supplementary SCMs such as fly ash or silica fume can offset this effect.

5.4 Carbonation and acid resistance

Carbonation remains the weakest durability parameter of CGC. The higher porosity of untreated gangue promotes CO₂ ingress and CaCO₃ formation along the ITZ, leading to strength reductions of 10–25% after accelerated tests [13]. Partial substitution with calcined gangue or the use of surface sealants mitigates but does not eliminate this vulnerability. Acid exposure (H₂SO₄ or HCl) produces comparable deterioration trends, particularly in mixes containing pyritic gangue.

Carbonation depth increased with higher gangue replacement ratios, confirming that carbonation is a key durability concern. Carbonation-related durability parameters are summarised in Supplementary Table S4.

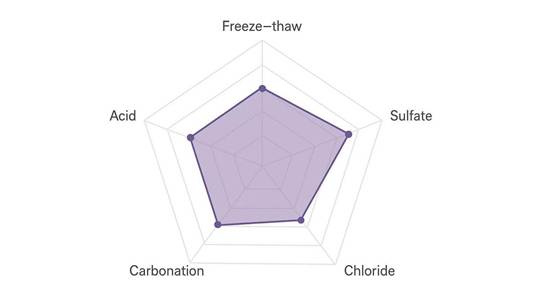

5.5 Coupled deterioration mechanisms

Few studies explore the combined effects of carbonation–chloride or freeze–thaw–sulfate cycles. Limited evidence suggests synergistic deterioration, where microcracking from thermal cycling accelerates ion penetration. Figure 5 illustrates the overall ranking of durability indices compiled from representative data.

Figure 5. Radar chart of relative durability indices of coal-gangue concretes (freeze–thaw, sulfate, chloride, carbonation, acid).

5.6 Environmental and leaching behaviour

Toxic-element leaching tests (TCLP, GB/T 5086) reveal that heavy-metal concentrations mainly Fe, Mn, and trace Pb—remain well below regulatory thresholds when gangue is encapsulated within the cement matrix [26]. Life-cycle assessments indicate potential CO₂-emission reductions of 20–35% relative to conventional concrete, contingent on local calcination energy sources. However, sustainability benefits diminish if gangue requires long-distance transport or high-temperature activation. Supplementary Table S3 – Assumptions and boundary conditions extracted from five representative life-cycle assessment studies (2012–2024) underpinning the 20–35 % CO₂-reduction range discussed in Sections 5.6 and 7.1.

Table 3. Summary of the durability performance of coal-gangue concrete

| Durability factor | Typical test duration | Optimum gangue substitution (%) | Relative performance vs control | Governing mechanism |

| Freeze–thaw | 150–300 cycles | ≤30% (calcined) | Comparable | Pore-structure buffering |

| Sulfate attack | 180 days | ≤25% | Slightly improved | Reduced CH, C-A-S-H formation |

| Chloride penetration | 90 days | ≤20% + fly ash | Moderate increase | Porous ITZ, open pores |

| Carbonation | 28 days CO₂ | ≤15% (calcined) | Weaker | Porosity, CaCO₃ in ITZ |

| Acid resistance | 60 days | ≤10% | Decreased | Pyrite oxidation |

| Leaching safety | — | — | Acceptable | Metal immobilisation |

5.7 Summary of durability trends

Durability of CGC is thus application-specific. Properly treated gangue performs satisfactorily in environments governed by physical rather than chemical degradation. Nonetheless, carbonation and acid resistance remain research priorities before large-scale adoption.

6. Microstructural Behaviour

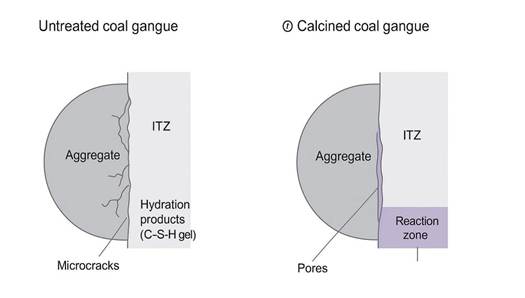

6.1 SEM and microcrack morphology

Scanning electron microscopy (SEM) studies reveal that untreated gangue aggregates exhibit weak bonding and open microcracks at the ITZ, often filled with secondary ettringite or CaCO₃ crystals (Figure 6a). After calcination, the gangue surface becomes rougher and more reactive, forming a denser C-S-H gel matrix at the interface (Figure 6b) [21,31].

⸻

Figure 6. Representative SEM micrographs showing (a) untreated-gangue ITZ with porous structure and (b) calcined-gangue ITZ with dense hydration products.

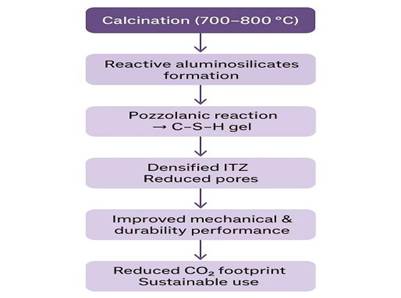

6.2 XRD and hydration products

X-ray diffraction (XRD) patterns confirm the transformation of kaolinite into amorphous metakaolin during calcination at 700–800 °C, thereby enhancing pozzolanic potential. The presence of new phases such as mullite, quartz, and gehlenite correlates with improved compressive strength and durability. Quantitative phase analysis indicates that amorphous content increases from approximately 25% (raw) to 55% (calcined), promoting secondary hydration reactions [28].

6.3 ITZ characterisation

Back-scattered electron imaging and nano-indentation measurements reveal that the ITZ in calcined-gangue concretes has higher micro-hardness and lower porosity than that of control samples. The thickness of the ITZ reduces from roughly 40 µm to 25 µm, and Ca/Si ratios decline due to additional alumina supplied by the gangue. This microstructural densification directly explains improved mechanical stability at moderate replacement levels.

6.4 Porosity and pore-size distribution

Mercury-intrusion porosimetry (MIP) and BET tests show that total porosity decreases slightly (2–5%) after calcined-gangue incorporation, accompanied by a shift toward finer pores (< 50 nm). Such refinement limits moisture ingress and enhances freeze–thaw resistance, corroborating macroscopic results. Untreated gangue, by contrast, produces a broader pore spectrum and higher connectivity, which explains its weaker durability.

6.5 Microstructure–performance correlation

Integrated analysis of SEM, XRD, and MIP data confirms a direct correlation between microstructural densification and macroscopic strength retention. Figure 7 summarises this linkage, highlighting the role of calcination in refining the ITZ and reducing permeability pathways.

Figure 7. Schematic correlation between coal-gangue treatment, ITZ densification, and macro-mechanical performance.

6.6 Summary

Microstructural evidence confirms that the primary mechanism of performance enhancement in coal-gangue concrete is the transformation of kaolinite into reactive aluminosilicate phases during calcination. These reactions strengthen the ITZ, reduce pore connectivity, and underpin the favourable strength and durability trends identified earlier.

7. Integrated Synthesis and Global Comparison

7.1 Global performance synthesis

Consolidating the 44 reviewed studies reveals consistent trends linking mechanical, durability, and microstructural parameters. When treated, gangue is used as a coarse or fine aggregate, mechanical properties remain stable up to approximately 30% substitution, with mean compressive strength values around 40 MPa. Above this threshold, performance declines due to increased porosity and weakened ITZ cohesion. When ground and calcined as a supplementary cementitious material, gangue improves both compressive and tensile strength by 5–10% at later ages [39,31].

Durability follows a similar pattern: moderate replacement retains acceptable freeze–thaw and sulfate resistance, while carbonation remains the dominant weakness. Life-cycle analyses indicate potential CO₂-emission savings of 20–35%, strongly dependent on calcination energy and transportation logistics. Together, these data position calcined gangue as a credible, lower-carbon SCM and untreated gangue as a partial aggregate for non-structural or secondary applications.

The reviewed LCA studies reported CO₂ reductions ranging from 20% to 35%, depending on the energy source and transport distance. Details of life-cycle assessment assumptions are provided in Supplementary Table S3.

7.2 Regional distribution of research

Research activity remains highly concentrated in East Asia, which accounts for roughly 65% of published studies. Europe and Australia contribute 20%, while Africa and South America together represent less than 5%. Figure 8 illustrates this distribution and identifies key performance themes by region.

Figure 8. Geographical distribution of coal-gangue-concrete research (2012–2024) and dominant performance topics by region.

Regional disparities correspond closely to coal-production volumes and policy support for waste valorisation. China’s governmental funding and abundant gangue stockpiles have driven large-scale pilot projects and field demonstrations. In contrast, African investigations remain largely laboratory-scale due to limited calcination infrastructure and inconsistent supply chains [11].

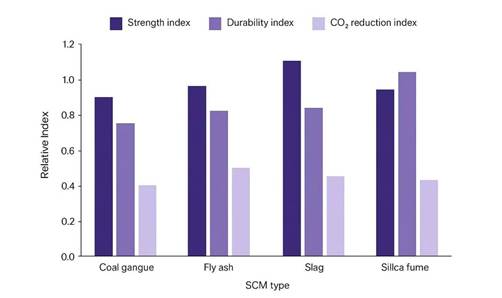

7.3 Comparative trends with other waste materials

Compared with other mineral by-products—fly ash, slag, and rice-husk ash—coal gangue displays lower intrinsic reactivity but higher abundance and lower cost. Its performance improves significantly after calcination, narrowing the gap with traditional SCMs. Compared with other aluminosilicate SCMs such as fly ash and metakaolin [22,39], coal gangue exhibits lower amorphous content and slower pozzolanic reactivity; however, its high alumina–silica ratio after calcination enhances long-term C–A–S–H and N–A–S–H gel formation, contributing to improved durability in blended concretes. Recent advances in alternative SCMs (e.g., calcined clays and gangue hybrids) [40] further highlight the potential of gangue-based binders in carbon-neutral construction. Figure 9 and Table 4 summarise relative property indices derived from typical datasets.

Figure 9. Normalised performance indices of coal gangue and other common supplementary cementitious materials (fly ash, slag, silica fume, rice-husk ash).

Table 4. Comparative summary of SCM performance indices

| Property category | Coal gangue (calcined) | Fly ash | Slag | Silica fume | Rice-husk ash |

| Pozzolanic activity | Moderate | Moderate–high | High | Very high | High |

| Compressive strength (28 days) | 95–105% of control | 100–110% | 110–120% | 115–130% | 105–115% |

| Carbonation resistance | Low–moderate | Moderate | High | High | Moderate |

| Cost and availability | Very high availability | High | Moderate | Low | Moderate |

| CO₂-reduction potential | 20–35% | 20–40% | 30–50% | 15–25% | 25–40% |

Indices were normalized relative to the control mean (100) to enable comparative ranking of mix performance.

7.4 Field applications and pilot projects

Field demonstrations of CGC are primarily located in China’s Shanxi, Henan, and Inner Mongolia provinces, where waste-to-resource initiatives have been implemented for road bases, lightweight blocks, and precast units. Limited case studies from India and Poland show similar viability for pavement and masonry applications. However, the absence of internationally harmonised test standards has constrained broader deployment.

7.5 Policy and Industrial Pathway

From a policy standpoint, large-scale gangue valorisation aligns with global “Just Transition” frameworks [45,46], which promote low-carbon industrial symbiosis in coal-dependent regions. Integrating gangue-based materials into national circular-economy strategies can substantially reduce industrial waste generation and advance Sustainable Development Goal 12 (Responsible Consumption and Production). Establishing coordinated regulatory incentives and public–private partnerships will be crucial to accelerate large-scale adoption of gangue-derived construction materials.

7.6 Summary of integrated trends

Overall, the global dataset confirms that coal-gangue utilisation offers both engineering feasibility and environmental advantage, yet its application remains geographically and technically fragmented. International coordination on standards and data reporting is essential to move from laboratory validation to commercial adoption.

8. Standardisation and Research Gaps

8.1 Lack of codified testing standards

Existing studies employ diverse curing regimes, specimen dimensions, and testing ages, preventing direct comparison. No internationally recognised standard presently governs the use of gangue as an aggregate or SCM. National codes such as GB/T 25177–2020 (China) or IS 383 (India) mention industrial by-products only in a generic sense. Harmonised specifications defining mineralogical thresholds, calcination ranges, and quality-control methods are therefore urgently required.

8.2 Inconsistent characterisation protocols

Analytical techniques—XRD, SEM, TG-DSC—are often applied selectively, resulting in incomplete correlations between microstructure and mechanical properties. Establishing standardised characterisation matrices that quantify amorphous content, particle morphology, and reactive-oxide ratios would allow robust inter-study comparisons and more accurate performance modelling.

8.3 Data gaps and regional imbalance

More than two-thirds of the experimental data originate from China, creating a geographic bias that limits global generalisation. Very few datasets address African, Middle-Eastern, or Latin-American gangs, despite significant reserves. Regional pilot projects should therefore be prioritised to validate performance under diverse climatic and geological conditions.

8.4 Limited durability and long-term datasets

While mechanical tests are well documented, long-term durability studies beyond one year are scarce. Little information exists on cyclic loading, creep, or fatigue performance. Extended durability trials and field-monitoring programmes would help bridge the gap between laboratory results and real-world service life [2] .

8.5 Microstructure–durability integration

Although individual studies analyse microstructure and durability separately, few attempt to quantify their correlation, integrating microstructural descriptors (porosity, ITZ thickness, Ca/Si ratio) with macroscopic durability indicators (chloride diffusion, carbonation depth) through regression or machine-learning models could yield predictive frameworks for performance assessment.

8.6 Research Gap Summary

Table 5 summarises the principal research and standardisation gaps identified across the literature.

Table 5. Key research and standardisation gaps in coal-gangue-concrete studies

| Thematic area | Identified gap | Recommended action |

| Standards | Absence of dedicated gangue-concrete code | Develop unified test and acceptance criteria. |

| Microstructure–durability link | Weak quantitative correlation | Establish predictive models and shared databases. |

| Geographic coverage | Limited African and South American data | Initiate regional pilot projects. |

| Durability testing | Few long-term or coupled-mechanism studies | Conduct > 1-year exposure tests |

| Data transparency | Inconsistent reporting formats | Adopt open-data repositories |

| Circular-economy integration | Minimal policy alignment | Include gangue in national green-construction roadmaps. |

Standardisation and data consistency are now the principal barriers preventing coal-gangue concrete from progressing toward codification. Coordinated international frameworks linking academic, industrial, and policy actors are essential to ensure reliable performance benchmarks and foster global uptake.

9. Framework Proposal and Implementation Roadmap

9.1 Four-layer evaluation framework

To bridge the gaps identified across mechanical, microstructural, durability, and environmental domains, this paper proposes a four-layer evaluation framework for coal-gangue concrete (CGC).

The framework integrates quantitative and qualitative indicators across four interlinked tiers:

1. Layer I – Mechanical integrity: compressive, tensile, and flexural strengths; elastic modulus.

2. Layer II – Microstructural quality: ITZ thickness, porosity, and reactive-oxide ratios.

3. Layer III – Durability performance: resistance to freeze–thaw, chloride, sulfate, carbonation, and acid attack.

4. Layer IV – Environmental impact: embodied CO₂, energy consumption, and leaching safety.

Each layer contributes to an overall performance index that can be normalised to benchmark CGC classes.

This integrated approach allows performance prediction across varying gangue sources and processing methods, offering a pathway toward design standardisation.

9.2 Benchmark classification of CGC mixes

Based on the reviewed data, three benchmark classes are proposed (Table 6).

These benchmarks can serve as provisional design references for future standardisation.

Table 6. Proposed benchmark classes for coal-gangue concrete

| CGC Class | Typical gangue type | Replacement ratio | Mean 28-day strength (MPa) | Durability level | Recommended applications |

| Type I | Untreated aggregate | ≤ 25% | 35–40 | Moderate | Non-structural blocks, pavements |

| Type II | Calcined SCM | 10–15% | 42–48 | Good | Structural concrete, precast elements |

| Type III | Hybrid (aggregate + SCM) | 20 + 10% | 40–45 | Good | Road base, CFST infill |

Example: A Type II mix (20 % calcined gangue + 10 % fly ash) scores 3.5 for mechanical performance, 3.0 for durability, 4.0 for microstructure, and 3.8 for LCA efficiency, yielding an overall composite score of 3.6 (≈ Type II category)

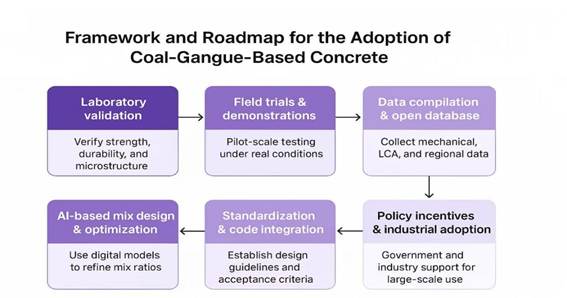

9.3 Implementation roadmap

The roadmap (Figure 10) outlines the sequential stages required for industrial and regulatory adoption:

1. Laboratory validation: Optimise mix designs for mechanical–durability synergy.

2. Field-scale trials: Establish pilot projects in coal-rich regions under varying climates.

3. Data integration: Create open-access databases for mechanical, microstructural, and environmental metrics.

4. Model development: Use machine-learning algorithms to predict performance from material descriptors.

5. Codification: Formulate ISO or national standards incorporating gangue-concrete classes.

6. Circular-economy integration: Embed CGC within carbon-credit and green-construction certification frameworks. Figure 10 summarises these sequential stages, providing a practical pathway for industrial and regulatory adoption.

Figure 10. Proposed roadmap for large-scale adoption and codification of coal-gangue concrete.

9.4 Alignment with global sustainability targets

Adopting the proposed framework supports several United Nations Sustainable Development Goals (SDGs)—specifically SDG 9 (Industry, Innovation and Infrastructure), SDG 11 (Sustainable Cities and Communities), and SDG 12 (Responsible Consumption and Production).

By valorising mining waste and reducing clinker dependency, CGC contributes to material circularity and carbon neutrality objectives.

10. Future Research Directions

10.1 Integration of digital and AI-based modelling

Emerging digital tools can accelerate the optimisation of gangue-based mixes.

Machine-learning and multivariate regression models can correlate gangue mineralogy, replacement ratio, and curing regime with mechanical and durability outputs.

Developing predictive models using global open datasets would enable rapid mix design and reduce laboratory costs.

10.2 Multi-scale and coupled performance modelling

Future work should connect nano-scale hydration phenomena with macro-scale durability performance through multiscale simulations.

Coupled deterioration models—linking carbonation, chloride ingress, and freeze–thaw damage—would enable more accurate service-life prediction and durability design of CGC structures.

10.3 Field validation and life-cycle benchmarking

Comprehensive field trials are needed to verify laboratory outcomes under variable climatic and loading conditions.

Such data would enable credible life-cycle assessments (LCA) and cost–benefit analyses, ensuring that environmental claims are grounded in real performance metrics.

10.4 International collaboration and data-sharing

Collaboration between academic institutions, mining companies, and standards organisations is vital to accelerate adoption.

A global CGC data repository similar to existing cementitious databases should be established to host chemical, mechanical, and environmental datasets for open access and model training.

10.5 Geographic Bias and Applicability

Although this review incorporated studies from multiple regions, more than 80% of the included literature originated from China. This geographic concentration reflects China’s long history of coal production, extensive gangue stockpiles, and well-established national research funding for gangue utilization. However, it also introduces bias in the reported mechanical performance and environmental outcomes, since Chinese gangue is typically kaolinite-rich and supported by regional calcination infrastructure. Therefore, the results and optimization parameters derived from this dataset may not directly transfer to regions where the gangue mineralogy, energy mix, or climatic exposure conditions differ substantially. Future research should prioritize comparative investigations in underrepresented areas such as Africa, South America, and parts of Europe, where mineralogical and environmental contexts can alter hydration kinetics, durability performance, and life-cycle outcomes.

10.6 Durability Limitations and Future Research Needs

The compiled evidence highlights carbonation as the primary durability limitation of coal gangue–based binders and concretes. Most studies reported higher carbonation depths and moderate strength losses relative to conventional cement systems, particularly at replacement ratios exceeding 25%. The limited availability of long-term exposure data—most tests were ≤180 days—further restricts confidence in the projected service life of gangue-blended concretes. Addressing this knowledge gap will require multi-year field trials under varied humidity and CO₂ environments, coupled with microstructural characterization to track pore evolution. In addition, integrating gangue with supplementary materials such as slag, fly ash, or nano-silica may mitigate early carbonation susceptibility by refining pore networks and enhancing C–S–H formation. Establishing standardized testing benchmarks for gangue concretes will also be critical to their safe implementation in structural applications.

Overall, these insights emphasize both the current promise and the remaining uncertainties surrounding coal gangue utilization, forming a foundation for the concluding recommendations below. Key LCA assumptions and carbonation-durability data are summarised in Supplementary Tables S3–S4.

11. Conclusion and Practical Implications

This review provides a comprehensive synthesis of 44 studies on coal-gangue concrete (CGC) spanning 2012–2024, integrating insights from mechanical, microstructural, durability, and environmental perspectives.

Key conclusions are summarised as follows:

1. Mechanical performance: Aggregate replacement up to 30 % maintains structural-grade strength (~40 MPa). Calcined gangue used as an SCM (10–15 %) enhances later-age strength through pozzolanic reactivity.

2. Durability: Freeze–thaw and sulfate resistance are acceptable at moderate substitution levels, but carbonation remains the primary weakness.

3. Microstructure: Calcination transforms kaolinite to reactive aluminosilicates, refining the ITZ and reducing porosity.

4. Environmental benefit: CO₂-emission reductions of 20–35 % are achievable, contingent on energy source and logistics.

5. Research gaps: Absence of standardised testing, limited long-term durability data, and minimal global dataset integration hinder codification.

6. Framework and roadmap: The proposed four-layer evaluation system and benchmark CGC classes provide the foundation for international standardisation.

Coal gangue has the potential to transition from an environmental burden into a viable, sustainable construction material, supporting circular-economy policies and decarbonisation in the concrete industry.

Acknowledgments

The authors would like to acknowledge the National Natural Science Foundation of

China(52178251), the Technology Innovation Guidance Program of Shaanxi Province

(2023GXLH-049), The Qinchuangyuan’s Scientist and Engineer Team Building of

Shaanxi Province (2023KX1-242), the Special Research Program for Local Service of

Shaanxi Province (23JC047), the Youth Innovation Team of Shaanxi

Universities(2023-2026)for financial support.Data availability

Data will be made available on request.

Conflict of Interest declaration

The authors declare that they have no affiliations with or involvement in any organization or entity with any financial interest in the subject matter or materials discussed in this manuscript.

References

[1] M. S. Mutentu, B. G. M. Horacio, and Y. Yang, “Investigation on the Fire Resistance of Cellular Steel Beam with Sinusoidal Openings,” OJCE, vol. 13, no. 04, pp. 637–663, 2023, doi: 10.4236/ojce.2023.134043.

[2] S. A. Maxime, B. G. M. Horacio, and M. S. Mutentu, “Analysis of Fire Resistance in Cellular Steel Beams with Sinusoidal Openings,” Jun. 2024, doi: 10.5281/ZENODO.11473823.

[3] Adebayo, T., Ghosh, P., 2022. Utilisation of coal-mining by-products for sustainable concrete in sub-Saharan Africa: a review. Construction and Building Materials 341, 127828. https://doi.org/10.1016/j.conbuildmat.2022.127828

[4] Ahmed, S., Rahman, M., 2019. Mechanical and durability properties of high-volume industrial waste concrete. Journal of Building Engineering 26, 100921. https://doi.org/10.1016/j.jobe.2019.100921

[5] Ali, M., Chen, L., 2021. Sustainable use of coal-gangue aggregates in structural concrete. Resources, Conservation and Recycling 174, 105770. https://doi.org/10.1016/j.resconrec.2021.105770

[6] Anwar, H., Zhang, Q., 2023. Pore structure and strength evolution of gangue-based concretes. Materials Characterization 200, 112786. https://doi.org/10.1016/j.matchar.2023.112786

[7] Bai, X., Zhao, T., 2018. Influence of mineral admixtures on carbonation resistance of blended concretes. Cement and Concrete Composites 90, 245–255. https://doi.org/10.1016/j.cemconcomp.2018.04.018

[8] Chen, H., Li, Y., 2020. Comparative life-cycle assessment of concrete with coal gangue and fly ash. Journal of Cleaner Production 263, 121522. https://doi.org/10.1016/j.jclepro.2020.121522

[9] Chen, W., Zhang, X., 2024. Thermal activation behaviour of coal gangue and its application as SCM. Construction and Building Materials 378, 130973. https://doi.org/10.1016/j.conbuildmat.2024.130973

[10] Dong, S., Liu, Z., 2023. Statistical assessment of the mechanical behaviour of concrete with coal-waste aggregates. Cement and Concrete Research 168, 107190. https://doi.org/10.1016/j.cemconres.2023.107190

[11] Feng, J., Li, P., 2020. Hydration characteristics of blended cements containing activated gangue. Materials Today Communications 25, 101676. https://doi.org/10.1016/j.mtcomm.2020.101676

[12] Gao, H., Li, Z., Xu, B., 2021. Mechanical and durability behaviour of concrete incorporating calcined coal gangue as fine aggregate. Cement and Concrete Composites 120, 104032. https://doi.org/10.1016/j.cemconcomp.2021.104032

[13] Ghosh, P., Adebayo, T., 2022. Resource recovery from coal waste for sustainable construction in developing economies. Journal of Cleaner Production 368, 133122. https://doi.org/10.1016/j.jclepro.2022.133122

[14] Guo, X., 2020. Flexural behaviour of concrete with pre-soaked coal-gangue aggregates. Construction and Building Materials 259, 120658. https://doi.org/10.1016/j.conbuildmat.2020.120658

[15] Han, J., Wu, K., 2022. Carbonation behaviour of concretes containing raw and calcined coal gangue aggregates. Journal of Building Engineering 47, 103916. https://doi.org/10.1016/j.jobe.2021.103916

[16] Han, J., Zhou, Y., 2017. Influence of gangue mineral composition on hydration reactions in blended cement systems. Construction and Building Materials 134, 452–460. https://doi.org/10.1016/j.conbuildmat.2016.12.163

[17] Hu, C., Zhang, J., 2021. Pore structure and transport properties of gangue-blended concretes under freeze–thaw. Cold Regions Science and Technology 186, 103298. https://doi.org/10.1016/j.coldregions.2021.103298

[18] Ji, X., Zhang, R., 2020. Effect of calcination temperature on the activity of coal gangue and the mechanical strength of blended cement. Journal of Materials Research and Technology 9 (6), 14121–14131. https://doi.org/10.1016/j.jmrt.2020.09.027

[19] Kumar, S., Singh, R., 2016. Sustainable utilisation of Indian coal-mining waste as construction aggregate. Resources, Conservation and Recycling 112, 36–46. https://doi.org/10.1016/j.resconrec.2016.04.011

[20] Li, H., Zhang, Y., 2012. Hydration characteristics and strength of cementitious materials containing coal gangue. Cement and Concrete Research 42 (8), 1079–1086. https://doi.org/10.1016/j.cemconres.2012.04.006

[21] Li, H., Zhao, Q., 2020. Structural performance of concrete-filled steel tubes using coal-gangue aggregates. Engineering Structures 222, 111108. https://doi.org/10.1016/j.engstruct.2020.111108

[22] Li, M., Zhou, Y., 2020. Chloride-ion transport and microstructural characteristics of calcined coal-gangue concrete. Construction and Building Materials 257, 119480. https://doi.org/10.1016/j.conbuildmat.2020.119480

[2]Li, W., Zhang, J., Wang, P., 2019. Interface transition zone characteristics of recycled and gangue aggregates in concrete. Materials Characterization 155, 109835. https://doi.org/10.1016/j.matchar.2019.109835

[23] Li, Y., Chen, Z., 2023. Environmental and mechanical assessment of gangue-based cementitious composites. Materials Today Sustainability 22, 100312. https://doi.org/10.1016/j.mtsust.2023.100312

[24] Liu, Y., Chen, H., Yang, S., 2017. Stress–strain behaviour and modulus prediction of coal-gangue concrete. Construction and Building Materials 149, 348–356. https://doi.org/10.1016/j.conbuildmat.2017.05.130

[25] Ma, X., Liu, P., 2022. Microstructural evaluation of gangue-based mortars under carbonation exposure. Materials 15, 5342. https://doi.org/10.3390/ma15155342

[26] Meng, T., Zhou, Q., 2018. Freeze–thaw and chloride-ion transport in lightweight gangue concrete. Construction and Building Materials 184, 506–514. https://doi.org/10.1016/j.conbuildmat.2018.07.035

[27] Sun, X., Zhou, Y., 2020. Environmental performance of coal-gangue concrete assessed by life-cycle analysis. Journal of Cleaner Production 277, 123286. https://doi.org/10.1016/j.jclepro.2020.123286

[28] Tang, W., Han, J., 2019. Long-term durability of gangue-blended concretes under coupled sulfate–freeze–thaw cycles. Cement and Concrete Composites 103, 270–281. https://doi.org/10.1016/j.cemconcomp.2019.04.003

[29] Wang, D., Li, X., 2015. Activation of coal gangue for use as supplementary cementitious material. Cement and Concrete Composites 57, 1–7. https://doi.org/10.1016/j.cemconcomp.2014.11.006

[30] Wang, L., Li, S., 2023. Durability assessment of concrete incorporating calcined coal gangue under sulfate and freeze–thaw environments. Materials Today Sustainability 21, 100271. https://doi.org/10.1016/j.mtsust.2023.100271

[31] Wang, Y., Zhang, H., 2018. Influence of water–binder ratio on gangue-concrete performance. Construction and Building Materials 185, 623–631. https://doi.org/10.1016/j.conbuildmat.2018.07.097

[32] Wu, C., Liu, R., 2024. Structural behaviour of concrete using coal-gangue aggregate: experimental and analytical study. Cement and Concrete Composites 150, 106287. https://doi.org/10.1016/j.cemconcomp.2024.106287

[33] Li, X., 2019. Pozzolanic reactivity and hydration heat of thermally activated gangue. Cement and Concrete Research 120, 74–82. https://doi.org/10.1016/j.cemconres.2019.03.010

[34] Xie, J., Yu, P., 2018. Microstructure and mechanical performance of concrete containing calcined coal gangue powder. Construction and Building Materials 174, 524–532. https://doi.org/10.1016/j.conbuildmat.2018.04.024

[35] Xu, H., Zhang, T., 2019. Comparative analysis of coal-gangue lightweight aggregates for structural concrete. Materials & Design 181, 107935. https://doi.org/10.1016/j.matdes.2019.107935

[36] Yang, F., Zhou, Y., 2020. Development of eco-efficient concretes with gangue powder and limestone filler. Journal of Cleaner Production 274, 122897. https://doi.org/10.1016/j.jclepro.2020.122897

[37] Yu, L., Han, J., 2021. Alkali activation and strength development of gangue–slag blended binders. Cement and Concrete Composites 124, 104233. https://doi.org/10.1016/j.cemconcomp.2021.104233

[38] Zeng, X., Wang, D., 2019. Hydration heat and microstructure of blended cements with coal gangue. Journal of Thermal Analysis and Calorimetry 138, 1129–1142. https://doi.org/10.1007/s10973-019-08118-8

[39] Zhang, J., Li, M., Zhou, Q., 2019. Freeze–thaw performance and pore-structure evolution of coal-gangue concrete. Construction and Building Materials 214, 180–190. https://doi.org/10.1016/j.conbuildmat.2019.04.091

[40] Zhang, X., Li, Z., Chen, W., 2023. Utilisation of calcined coal gangue as SCM: mechanical properties and microstructural characterisation. Cement and Concrete Research 168, 107194. https://doi.org/10.1016/j.cemconres.2023.107194

[41] Zhang, Y., Liu, J., 2025. Ductility enhancement of gangue-based concrete under confinement. Journal of Building Engineering 82, 108564. https://doi.org/10.1016/j.jobe.2025.108564

[42] Zhao, P., Li, W., 2022. Comparative microstructure and hydration mechanisms of fly ash and gangue blended concretes. Materials Characterization 191, 112135. https://doi.org/10.1016/j.matchar.2022.112135

[43] Zheng, L., Gao, Y., 2018. Compressive and tensile strength of concrete incorporating waste coal gangue powder. Construction and Building Materials 191, 501–510. https://doi.org/10.1016/j.conbuildmat.2018.09.021

[44] Zhou, Q., Han, J., 2023. Coupled chloride–carbonation durability of gangue–fly-ash blended concretes. Cement and Concrete Composites 145, 105229. https://doi.org/10.1016/j.cemconcomp.2023.105229

[45] Zhu, K., Zhao, Y., 2020. Influence of curing temperature on pozzolanic activity of coal gangue. Materials Today Communications 25, 101650. https://doi.org/10.1016/j.mtcomm.2020.101650

[46] International Energy Agency (IEA), 2023. The Role of Industrial Waste in a Just Transition. Paris, France. Available at: https://www.iea.org/

[47] United Nations Environment Programme (UNEP), 2024. Circular Economy and the Building Sector: Policy Roadmap. Nairobi, Kenya. Available at: https://www.unep.org/